Vertical control joints in masonry facades serve a similar purpose to horizontal control joints, but with some differences in placement and function. Both types of control joints are designed to accommodate minor movement and stresses in the masonry wall system caused by temperature changes, settlement, moisture, etc. This helps control cracking and deterioration. We don’t always see significant control joints built into typical DC historic brick masonry rowhomes, but they are needed to prevent severe structural problems in larger brick buildings.

Vertical control joints are placed at intervals along a wall’s length, from foundation to parapet. Typical spacing is 20-30 feet. They are most often continuous thin saw-cut gaps that penetrate the entire masonry wythe and are filled with a flexible sealant.

Horizontal control joints (also called expansion joints) are located at floors/levels, lintels, and other areas prone to differential movement. They allow the separate wythes above and below to expand and contract independently. Unlike saw-cut vertical joints, horizontal control joints can be created right at an otherwise typical horizontal bed joint in the masonry.

Some key similarities between vertical and horizontal control joints:

- Both accommodate stress and minor structural movement

- Both prevent and control cracks by creating planned weak points, a path of least resistance.

- Sealant-filled gaps allow flexibility

Some key differences between vertical and horizontal control joints:

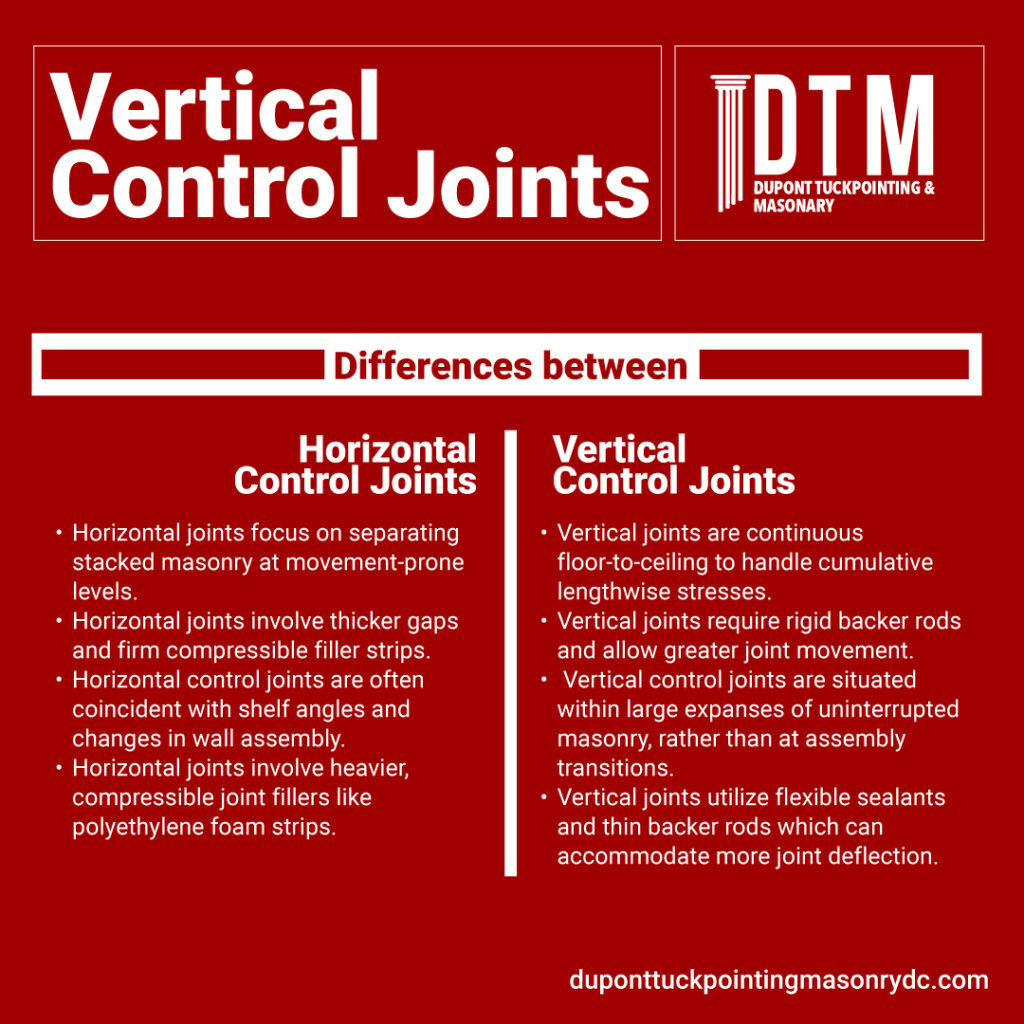

- Vertical joints are continuous floor-to-ceiling (and beyond up and down a facade in multiple story masonry exteriors) to handle cumulative lengthwise stresses. Horizontal joints focus on separating stacked masonry at movement-prone levels.

- Vertical joints often require rigid backer rods and allow greater joint movement.

- Horizontal joints often involve thicker gaps and firm compressible filler strips.

Proper placement, detailing, and sealant selection for both types of control joints are critical to create long-lasting, weather-tight joints that accommodate movement and prevent deterioration in masonry facades. They serve dual and complementary roles in both preventing exterior moisture ingress and managing stress while allowing structural movement.

While both types of joints serve important roles in masonry facades, there is a key difference in that horizontal control joints are often coincident with shelf angles and changes in wall assembly. In many modern wall systems, the exterior wythe of masonry acts as a veneer or decorative skin, with the structural loads carried by a separate backup wall. This type of construction with an exterior skin and a veneer type brick at the exterior of the building is not found in historic construction, it’s something that is only used within the past 60-80 years in what we considered contemporary or modern construction. In fact the earliest uses of a brick veneer or exterior skin, found in Washington DC usually occur at buildings that were built with a mixture of CMU and brick, see me use all so known as cinder block but the abbreviation stands for concrete masonry unit.

Horizontal control joints occur at floors where the masonry transitions from one section to another, such as above shelf angles. This allows the masonry wythes to expand and contract independently without compromising structural integrity. The shelf angle provides an attachment point and separates the exterior masonry veneer from the main wall system.

In contrast, vertical control joints are situated within large expanses of uninterrupted masonry, rather than at assembly transitions. Their purpose is mainly to accommodate cumulative stresses along lengthy walls due to minor movement over time. Vertical joints are placed at regular intervals in field areas where cracking could otherwise occur.

As mentioned in the bullet list above, a key difference is that horizontal joints often use heavier, compressible joint fillers like polyethylene foam strips. These support the masonry while allowing movement at the shelf angle. Vertical joints utilize flexible sealants and thin backer rods which can accommodate more joint deflection. Some side to side lateral movement may occur at the ankle bearing points of masonry skin or veneer walls, but a greater degree of movement is expected at vertical control joints.

The masonry skin separated by horizontal control joints often acts solely as a rainscreen and aesthetic element. It is not necessarily a true vapor barrier or air barrier, like the backup wall behind it. Vertical joints only pass through the masonry wythe and do not change the wall composition.

While both joint types manage stress and movement, horizontal control joints specifically address transitions between wall assemblies, align with structure, and allow for greater differential movement. Vertical joints are more narrowly focused on reducing continuous flexural stresses within lengthy intact runs of uniform masonry. Their placement and components target different scenarios.

Historic load-bearing brick walls were composed of multiple stacked wythes of brick, ranging from 2 to 3 layers thick, creating an overall wall thickness of 8 to 12 inches, in most cases. The brick units were normally laid in interlocking bond patterns, most often English or Flemish bonds (and common bond), with overlapping header and stretcher courses that provided stability and structural integrity. The mortar used was a lime-based mixture to create strong adhesive bonds between the masonry units. Together, the fired clay brick material and lime-cement mortar provided a durable assembly capable of carrying all primary loads including gravity, lateral, and wind forces. The masonry structure relied on the quality and strength of the bricks and mortar to maintain stability, as there was no separate structural framework. The cohesive bonded wythes of brick spanning the full wall thickness functioned as the load bearing structure.

In contrast, modern brick veneer walls utilize a non-structural single wythe of brick as an exterior cladding layer, typically 4 inches thick, attached to a pre-existing structural substrate. The brick ties back to a concrete or steel-frame building structure using metal ties and anchors embedded in mortar joints. Flashing, drainage mats, weep holes, and air spaces create a moisture-managed rainscreen assembly. With only a single thin wythe rather than interlocking multi-wythe masonry, the decorative brick veneer is not designed to carry gravity or lateral loads. The adhesive mortar bonds bricks together solely to maintain the facade stability rather than for structural strength like historic walls. The contemporary best practice of allowing controlled differential movement through properly placed expansion joints also differs from traditional fully bonded historic brickwork. In summary, modern brick cladding relies on ancillary components to provide structural performance, moisture protection and managed movement rather than deriving these directly from the masonry itself.

Our company, Dupont Tuckpointing and Masonry, specializes in masonry restoration, historic brick repointing, and tuckpointing services in the Washington D.C. area. These buildings are uniquely historic, and their preservation requires skilled masons who are technically trained in the best practices and knowledge of proper restoration techniques.

We understand the significance of maintaining the architectural integrity of these historic structures, and our team of experienced professionals is dedicated to delivering exceptional craftsmanship. Whether you require masonry restoration, tuckpointing, or brick repointing services, we are here to help.

At Dupont Tuckpointing and Masonry, we take pride in our work and strive to ensure that every project is executed with the utmost care and attention to detail. We are committed to preserving the rich heritage of Washington D.C.’s built environment for generations to come.

If you have any questions or needs regarding masonry restoration, historic brick repointing, or tuckpointing services, please do not hesitate to reach out to us. We would be delighted to assist you and provide you with the expertise and quality workmanship that your historic property deserves.

You can reach us by telephone at (202) 796-7644 and you can reach us by email from the contact form on our website at https://duponttuckpointingmasonrydc.com/contact-us/.